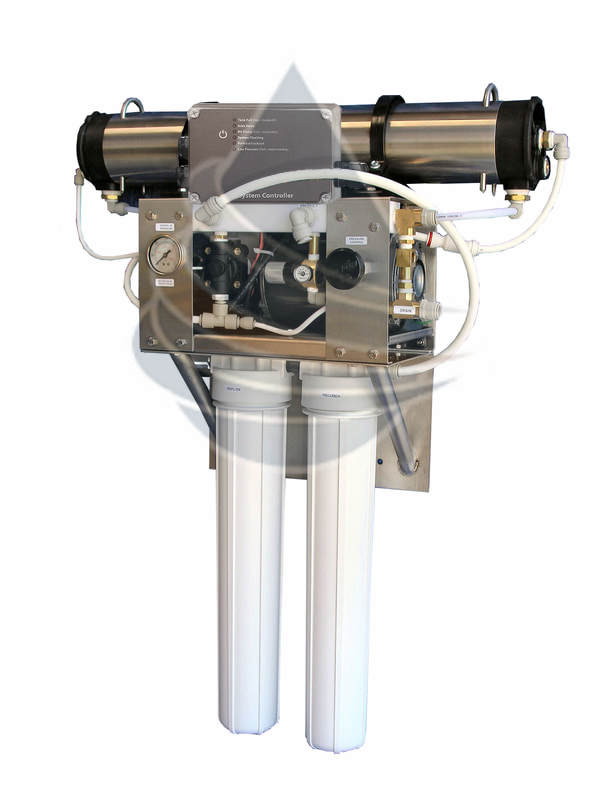

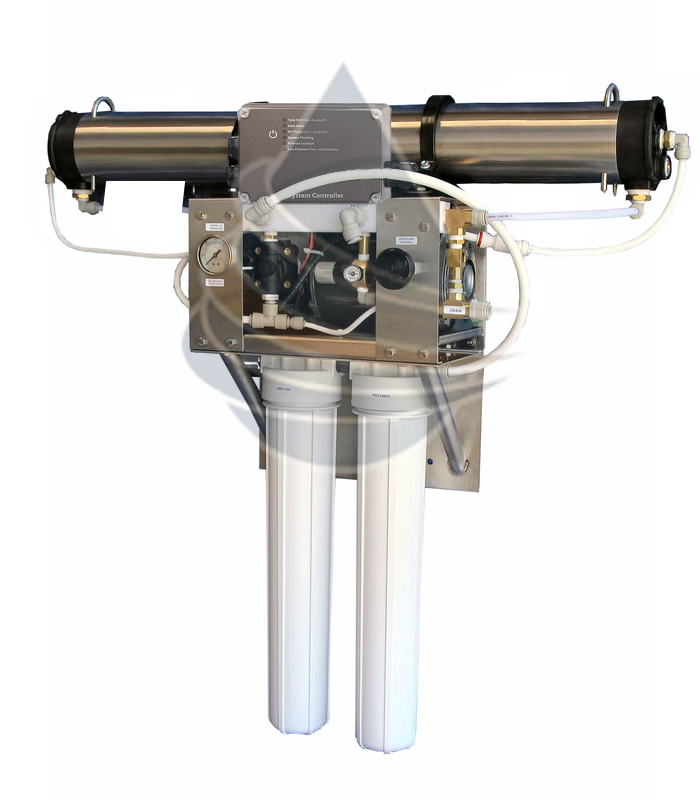

The Stainless Steel Wall Mount Reverse Osmosis Systems

Commercial RO Selection Guide: Complete Commercial RO Catalog | Compact 400-1,500gpd RO Systems | 2,000-12,000gpd RO Systems | Skid Mounted RO Systems | Nanofiltration Systems | Sea Water RO Systems

Our 400gpd-1500gpd light commercial reverse osmosis water purifiers are built to suit the needs and requirements of the commercial business. This includes restaurants, coffee & tea stores, marijuana growers, craft beer & microbreweries, supermarket produce and food preparation operations, misting and humidification systems, car wash facilities, and many other businesses that must have consistent high quality water for their daily operations. The key factors of reliability, serviceability, and consistent performance with minimum user intervention are achieved in the solid design of the RO systems. Stainless steel is used throughout; in frame, pressure vessels and fastening hardware to provide the structural strength and corrosion resistance appropriate for a commercial appliance.

400gpd - 1500gpd Reverse Osmosis Components & Features:

-

Installation Tubing: RainDance is including color-coded tubing and easy quick-connect fittings for your commercial RO system to make installation a breeze. Color tubing coordinates with the RO feed water (white), product water (blue), and drain water (yellow). Includes 3 sets of 20ft flexible 1/2" tubing.

-

Pressure Vessel/Membrane Assembly: This is where the dissolved solids are separated from the feed water. This assembly consists of 1 316 SS pressure vessel that houses the reverse osmosis (RO) membrane. Stainless steel pressure vessels are standard on all 4 models.

-

Pump: The pump boosts water pressure in the pressure vessel/membrane assembly to about 150 psig to ensure high dissolved solids rejection and high flow rates.

-

Motor: Used to drive the pump. Motors are Open Drip Proof construction (OPD) with thermal overload protection.

-

Electronic Controller: The electronic controller accepts input commands and signals to control operation of the R.O. system. Continue scrolling down this page or Click Here to read more about this state-of-the-art controller.

-

Solenoid Valve: Electrically operated valve that prevents water from flowing through the system when it is not in operation. The coil and body are separate replaceable units.

-

Brine Flow Control: This assembly contains the orifice flow restrictor sized to produce approximately 125-175 psi in the pressure vessel/membrane.

-

Vessel In Pressure Control Valve: A needle valve that controls the amount of brine from the membrane to be re-circulated back into the feed stream. This feature allows for higher recovery rates, This valve provides control of system operating pressure as well as brine flow rate and TDS.

-

Tank Pressure Gauge: This gauge displays the pressure within the product water bladder storage tank. If the R.O. system is supplying product water to an atmospheric storage tank this gauge will always read zero. Click Here to view our bladder tank options.

-

Vessel-In Gauge: This gauge displays the operating pressure at the inlet of the membrane pressure vessel. This pressure indication is used in the setup of the unit and as an early warning of membrane fouling.

-

Fast Flush Valve: This valve is located on the brine flow control assembly and provides a means of bypassing the flow restrictor orifice. Periodically (at least monthly) this valve should be turned to vertical for 30 to 60 seconds and then returned to the horizontal position while the system is running. This will provide a momentary high velocity, low pressure flow across the membrane to help flush away any accumulated particles or debris.

-

Product Water Check Valve: This valve is located in the product line coming out of the membrane pressure vessel. It acts to prevent back flow of product water from the pressurized storage tank into the membrane when the system is not operating.

-

Low Feed Pressure Switch: This pressure switch provides a signal to the electronic controller to turn off the system in the event of low incoming feed pressure. It is factory set to cut off if the pressure drops below 15 psi.

-

Atmospheric Storage Tank Float Switch: Pre-installed Float Switch - Conserves water! Shuts RO system off when storage tank is full. Includes one float switch and weight for system control by tank level. Click Here to view our atmospheric storage tank and pump options.

-

Reverse Osmosis Frame: The system frame includes a base and two channel frames fabricated in stainless steel. All fasteners on the system are stainless steel. The frame provides a mounting for all the RO system components.

-

Rubber Feet: These allow for a stable mounting on an uneven surface and for vibration and sound mitigation.

-

Inlet Feed Water Port: Filtered feed water is supplied to the system via this 1/2” tube size quick connector.

-

RO Product Water Port: Purified product water leaves the system via this 1/2” tube size quick connector. Typically this connector will be plumbed to the product water storage tank.

-

RO Drain Port: Concentrated brine water leaves the system through this 1/2” tube size quick connector.

-

Support Equipment: Sediment & carbon de-chlorination and chloramine removal pretreatment filters are included to prevent premature fouling and prolong the life of the RO membrane. Click Here to view other pretreatment options.

-

Replacement Filters: All RO systems include a 3 year supply of sediment & carbon prefilters at no extra charge.

-

Testing Equipment: Separate pH, conductivity (ec), total dissolved solids (TDS) and water temperature monitors are included to assure your RO system is working at optimum performance.

-

Water Totalizing Meter - Our reverse osmosis totalizing meter accurately displays how many gallons of water you are using, making it easier for you to monitor your daily water use and track how many gallons are running through the filters.

-

Blending Valve: A blending valve can be added at no extra cost! The blending valve allows the addition of filtered feed water to the product of the RO system. This is done when the product of the RO system is a lower TDS than is necessary or desired. Contact us for more information.

-

Shipping: We offer free delivery within the continental USA

-

Got Beer? We design commercial reverse osmosis water packages specifically for the beer industry including craft beer, micro-breweries and commercial beer & beverage makers. Click Here to view options.

Ask About Our Current Online Discounts & Specials Before Ordering

Operating Parameters: Max TDS-2500ppm, Total iron is less than 0.3ppm, Manganese is less than 0.05ppm, Water hardness below 5 gpg.

A: The Electronic Control Panel with function indicators provides hands-free and worry-free operation of several functions of the RO system. The basic RO functions include the "feed pressure switch" and "tank float switch" which regulates the system operating. The "feed pressure switch" ensures that your incoming water pressure is high enough for the RO system to operate (typically above 25psi). The "tank float switch" tells the RO system to shut down or start up based on your storage tank's water level. These basic functions are built into the RO control panel for smarter regulation and eliminates external switches.

A bonus feature included in our Electronic RO Control Panel is automatic membrane flushing. Most whole house/light commercial RO systems on the market today do not provide a membrane flush, which helps extend the life of the membrane by removing the concentrate brine (extremely salty water expelled by the membrane) sitting on the surface. Our previous whole house and light commercial RO systems included a manual membrane flush that allowed the user to flush the membrane as they wanted to. With this Electronic RO Control Panel, our customers no longer need to worry about remembering to flush the membrane constantly; this control panel automatically activates a membrane flush both at start up and shut down, ensuring longevity of your RO membrane.

The most important feature on this control panel, however, is the low pressure shutdown. Both public city water users and private well water users can suffer from periods of low pressure which can have a great negative affect on any RO system. If you experience a period of low pressure, a standard RO system would cycle on and off until the pressure is regulated. This can cause wear and irreversible damage to the RO pump motor and external feed pressure switch, resulting in costly, down-time and labor-intensive repair. Our RO control panel prevents this from happening by automatically shutting down the RO system if your feed pressure remains low for an extended period of time.

An optional feature on our RO control panel is pretreatment lockout. When pretreatment is needed to protect the RO system, a backwashing filter or water softener is used. When these pretreatment systems shut down to clean themselves, they allow unfiltered water to pass by the system and get into the RO if it's running at this time. To prevent possible exposure to unfiltered water a pretreatment lockout switch can be used to shut down the RO system when the water softener or filter is regenerating. Once the pretreatment system is finished regenerating, the switch will reactivate the RO system again. Both the RO system and the pretreatment system will need to be specially fitted with pretreatment lockout. This option is included free of charge when you add any of our pretreatment water softeners, iron filters, or backwashing systems to your RO Package!

Each function of the control panel is displayed with varying indicator lights to let you know how the system is running. You won't have to wait until it's too late and there is no water when you turn on a tap. Our Electronic RO Control Panel prevents potential RO malfunctions from happening and allows you to catch the culprit in time, before it has a chance to harm your system. This fully automated control is a must-have for any home or business owner that wants a hassle-free solution to many water problems.

In almost all reverse osmosis applications, providing pretreatment for the feed water protects and extends the life of the purification. While there are some exceptions, some type of pretreatment equipment is almost always used to protect the RO system. We offer complete pretreatment capabilities that include, iron filters, sediment removal, water softeners, chlorine filters, antiscalant systems, UV ultraviolet disinfection and more. Contact Sales@RainDanceWaterSystems.com for all your pretreatment needs. Note: Any free pretreatment offers will be included in your quote.

Do you require commercial RO pretreatment or have an outdated water softener system?

Consider our RainDance PRO Water Softener custom built for both city water and well water users! Our all-in-one pretreatment system specifically built to protect our RO Packages. Now with pretreatment lock-out!

Reverse Osmosis Atmospheric Storage Tank Options

Reverse osmosis systems produce water as a small

stream, so a separate storage tank is needed to store water for use.

Add one of our storage tanks below or

source your own tank and we will include a float and float switch at

no extra charge!

Reverse Osmosis Repressurization Delivery Pump